| |||||||

|

|

|||||||

|

|

|||||||

| Mechanisms and Mechanics of Composite Joints | |||||||

|

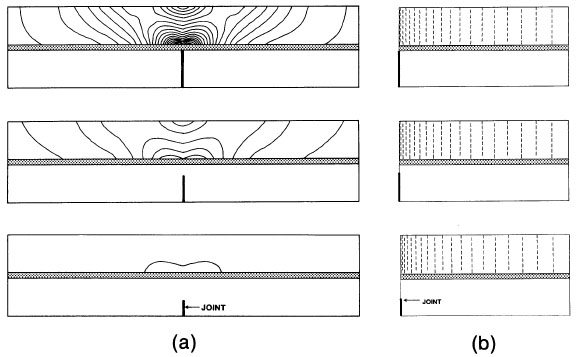

For a composite joint set, there is a trend observable between the ductile layer thickness and the distance between the side-stepping joint segments in adjacent layers, referred to as stepping offset. The thicker the ductile layer, the larger the stepping offset (Figure 1c, Helgeson and Aydin, 1991). As the ductile layer approaches a thickness about equal to that of the brittle layers, the alignment of the joint segments in the two brittle layers can no longer be observed. A theoretical explanation for this trend can be found in considering joint propagation across inhibiting mediums of varying thicknesses such as thin shale layers or laminas, but it should be generally applicable to all mediums which are resistant to brittle fracturing. Consider an opening mode fracture in a brittle layer propagating towards the interface between a brittle-ductile multilayer sequence. This problem has been analyzed by Helgeson and Aydin using a finite element model. They found that the highest stresses first occur out-of-plane of the approaching joint at two symmetric regions in the layer ahead of the joint (Figure 2). The thicker the ductile layer between the elastic layers, the further away from the in-plane extension of the approaching joint the highest stresses occur. Based on a maximum tensile stress criterion, a new joint segment would initiate when the fracture toughness of the rock is reached. Propagation of the new segment in one of these two regions would continue upward (or downward) in a direction nearly perpendicular to the layer until it reaches the next ductile layer. This incremental progressive process would continue, layer after layer, until ultimately the conditions required for joint propagation no longer exist. | |||||||

| Reference: |

|||||||

| Helgeson, D., Aydin, A., 1991 |

|||||||

|

Readme | About Us | Acknowledgement | How to Cite | Terms of Use | Ⓒ Rock Fracture Knowledgebase |

|||||||