| |||||||||

|

|

|||||||||

|

|

|||||||||

| Surface Morphology of Pressure Solution Seams | |||||||||

|

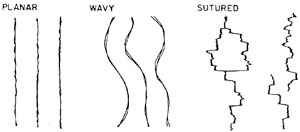

Pressure solution seams have various shapes. They can be planar, sinusoidal or wavy, and suture (Figure 1). The terms planar and wavy describe on a larger scale the enveloping surfaces of pressure solution seams.

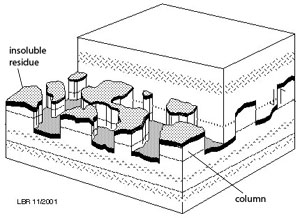

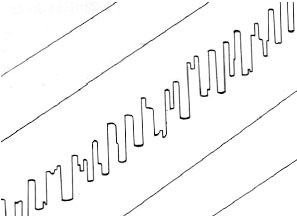

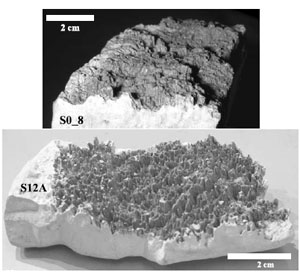

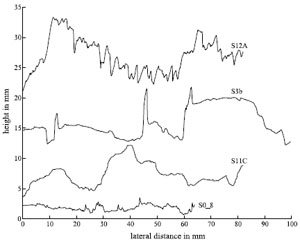

Suture describes the 2D cross section of pitted architecture (Figure 2 and 3). Those with sutured shape are called stylolites. Individual columns of stylolites are almost always parallel to the direction of compression. The overall plane of dissolution normally follows existing weaknesses such as bedding interfaces. Thus, in undisturbed strata in original horizontal position, the stylolite columns are at right-angle to the bedding interfaces, but in inclined strata like limbs of folds where dissolution occurs after the tilting of layers, they are not (Figure 3, Stockdale, 1922). Trurnit (1968) suggested that the relative solubility on the two sides determines the shape of the solution seams. The sutured stylolites are characteristic of contact of equal solubility on both sides and smooth contacts are characteristic of unequal solubility materials where only the more soluble material or layer dissolves. However, Guzetta (1984) proposed that distributed insoluble grains or crystals enhance the roughness of dissolution surfaces or seams. A thick zone of insoluble residue acts like a more insoluble solution partner and favors smooth solution seams. Renard et al. (2004) separated 12 bed-parallel stylolites into two adjacent surfaces in limestone (Figure 4) and measured the three-dimensional geometry of the surfaces using a laser profilometer (Figure 5).

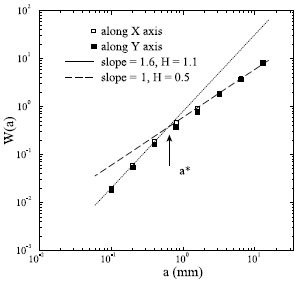

These authors calculated the statistical characteristics of the surfaces and concluded that all the stylolites have self-affine fractal roughness with a well-characterized crossover length scale separating two self-affine scaling regimes (Figure 6). Strikingly, the characteristic length scale falls with a very narrow range for all the stylolites studied, regardless of the size of microstructures. To explain the data, the authors proposed a continuous phenomenological model that postulates that the complex morphology of stylolites is the result of competition between the long-range elastic redistribution of local stress fluctuations responsible for the surface roughness and surface tension along the interface which tends to smooth it, corresponding to the two scaling regions in Figure 6. | |||||||||

| Reference: |

|||||||||

| Guzzetta, G., 1984 Renard, F., Schmittbuhl, J., Gratier, J.P., Meakin, P., Merino, E., 2004 Stockdale, P.B., 1922 Trurnit, P., 1968 |

|||||||||

|

Readme | About Us | Acknowledgement | How to Cite | Terms of Use | Ⓒ Rock Fracture Knowledgebase |

|||||||||