| |||||||

|

|

|||||||

|

|

|||||||

| Growth of Faults based on Shale Smearing | |||||||

|

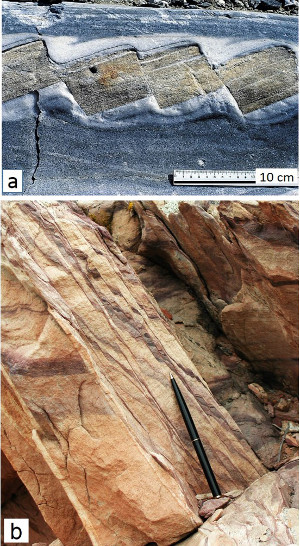

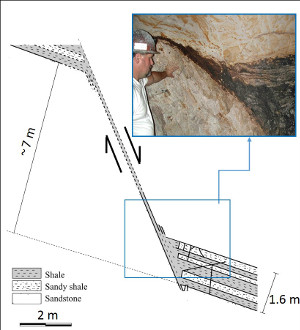

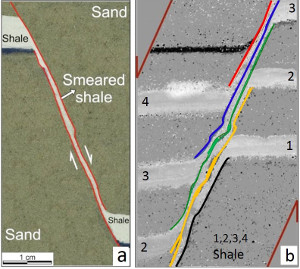

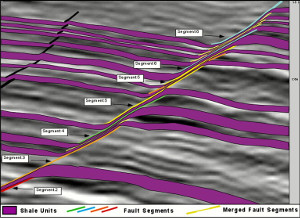

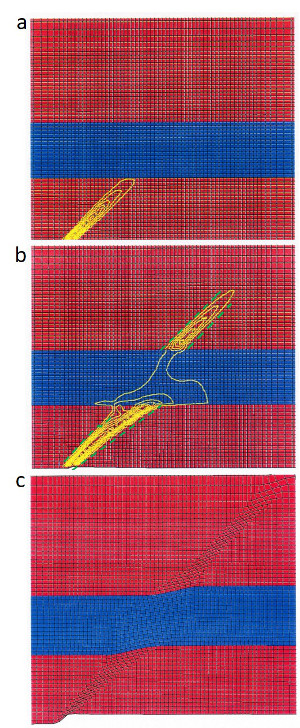

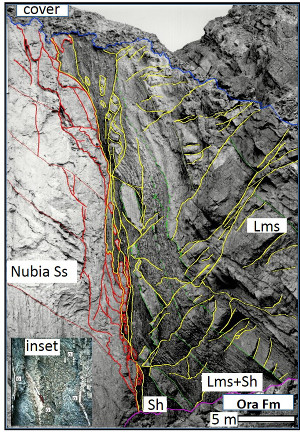

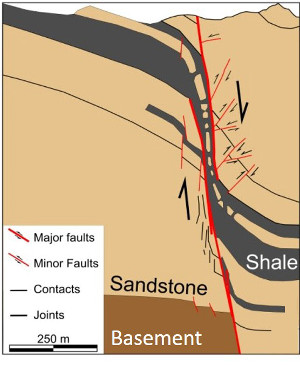

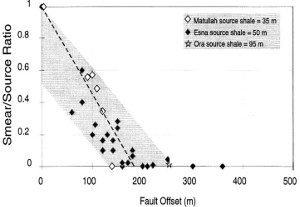

Fault growth in multi-layered rocks made up of stiff (competent-brittle) and soft (incompetent-ductile) lithologies subjected to extension and normal faulting produces a completely different deformation geometry and style which has long been well-known as shale or clay smear in structural geology. The basis of this style of deformation can be seen in a photograph in Figure 1(a) in which a detrital unit embedded between anhydrite layers is deformed by different modes. The extension of the brittle detrital rock by normal faulting and the stretching of the anhydrite layers on both sides by plastic flow result in what is called a boudinage structure. If the ductile or viscous units are mudstone or shale embedded within brittle sequences such as sandstones or limestones, then the shale layers deform by smear faults as shown in Figure 1(b). This is generally referred to as shale or clay smear in structural geology and petroleum geology. One of the best examples of this phenomenon from an underground mine in California has been described and analyzed by Eichhubl et al. (2005), where a shale unit of 1.6 m thick has been entrained and attenuated forming a thin smear of locally less than a few centimeters thick along a normal fault of about 7 to 8 m offset (see map in Figure 2 and the inset photograph). Similar deformation styles have been produced in experiments using various materials, commonly sand and clay as stiff and soft layers, respectively. Figure 3(a) illustrates a single layer which deformed along a normal fault instigated by a moving basement (Noorsaley-Garakani et al., 2013). Figure 3(b) is another example from an analog experiment using multi clay layers (Schmatz et al. 2010; in http://www.ged.rwth) with large enough applied offset resulting in the merging and coalescing of closely spaced clay layers. Figure 4 is a visualization of a more complex configuration interpreted from a subsurface seismic data set involving multi shale units embedded within sand deposits (Koledoye et al., 2000, 2003). The normal fault array on the left-hand side has limited offset and the shale layers and the fault segments are distinctly separate. The array on the right part of the section has tens of meters offset and the smeared shale rocks and the bounding faults merged or coalesced. Some shale units along the normal fault array may have disappeared completely. There are two critical elements in the process of smear faults: The first one is the ductility or viscosity of shale, which is a prerequisite because otherwise it would behave like any other multi-layer brittle rock. The second one is the sense of off-plane jump of the brittle failure structures across the ductile layer, which experiences dilatant plastic strain analogous to necking in metal plasticity. These concepts are supported by a series of FEM numerical experiments with a viscous layer embedded in an elastic-plastic medium subjected to lateral extension (Dawson and Aydin, 1999). The failure occurs in the form of strain softening across a few grids at the bottom side of the viscous layer, probably due to a boundary effect (Figure 5(a)). This localized discontinuity of the strain rate is called 'smear crack' in mechanics. The jump of the localized shear strain to the top layer occurs out of plane in such a way that the extensional plastic or viscoplastic deformation of the softer middle layer is accommodated as the shear strain on the segments increases. Dashed green lines bounding the smeared cracks in the figure illustrate the lateral shift of the localized zones as the lower smeared structure jumps over from bottom layer to top layer. The line markers were removed in Figure 5(c) to show the segments. The stepover structure is an extensional shear band for the lack of any better term. A similar jumping across soft layers occurs when an opening mode fracture or joint tends to cross a shale layer (Helgeson and Aydin, 1991). Although rare, the failure structures on either side of a shale layer may form a contraction step, an example of which is provided in the echelon faults section. In this case, the segments are independent of each other and the shale in the middle may be squeezed out into the top or bottom layers by extrusion. It of course follows that variable distribution of soft and stiff units produces highly complex depositional and structural configurations in nature. Figure 6(a) is an example for such a complex normal fault with about 250 meters offset (Aydin and Eyal, 2002). There, a member of the formation (Ora Formation) is a shale unit of about 60 meters thick that is undeformed at the right side of the picture, but has been attenuated along the high-angle normal fault to the brink of becoming discontinuous. Also notice the strings of brittle layers embedded within the lower part of the shale unit as boudins as well as many oblique faults accommodating deformation adjacent to the major fault on their hanging wall as conceptualized in Figure 7. In subsurface applications of the shale deformation concepts to petroleum geology (Yielding et al., 1997; Vrolijk et al, 2016) and hydrogeology (Bense et al., 2013; Ciftci et al., 2013; Cilona et al., 2014), it is desirable to estimate the reduction of the smear thickness, particularly at its vanishing point. Figure 8 is a plot of smear thickness normalized by the undeformed thickness of three shale units versus throw for several predominantly normal faults in the eastern Gulf of Suez, Egypt. Where data is available, the smear thickness decreases as the amount of offset increases for the same fault and the decreasing smear shale or fault rock thicknesses correspond to progressively larger offsets of the shale units surveyed (Data from Younes and Aydin, 1998; Aydin and Eyal, 2002). In the presence of multiple shale units in close proximity to each other within the same formation, merging of smeared shale units may occur as pointed out above. | |||||||

| Reference: |

|||||||

| Aydin, A., Eyal, Y., 2002 Bense, V.F., Gleeson, T., Loveless, S.E., Bour, O., Sciebek, J., 2013 Ciftci, N.B., Giger, S.B., Clennell, M.B., 2013 Cilona, A., Aydin, A., Johnson, N.M., 2014 Cilona, A., Aydin, A., Likerman, J., Parker, B., Cherry, J., 2016 Dawson, E.A., Aydin, A., 1999 Eichhubl, P., D'Onfro, P.S., Aydin, A., Waters, J., McCarty, D.K., 2005 Koledoye, B., Aydin, A., May, E., 2000 Koledoye, B., Aydin, A., May, E., 2003 Noorsalehi-Garakania, S., Kleine Vennekate, G.J., Vrolijk, P., Urai, J.L., 2013 Schmatz, J., Vrolijk, P., Urai, J.L., 2010 Vrolijk, P., Urai, J.L., Kettermann, M., 2016 Yielding, G., Freeman, B., Needham, T., 1997 Younes, A.I., Aydin, A., 1998 |

|||||||

|

Readme | About Us | Acknowledgement | How to Cite | Terms of Use | Ⓒ Rock Fracture Knowledgebase |

|||||||