| |||||||

|

|

|||||||

|

|

|||||||

| Growth of Joint Arrays - Fracture Saturation and Fracture Infilling | |||||||

|

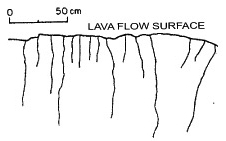

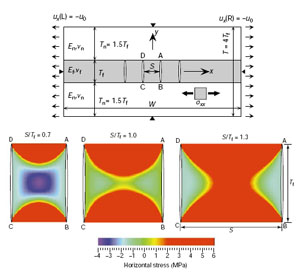

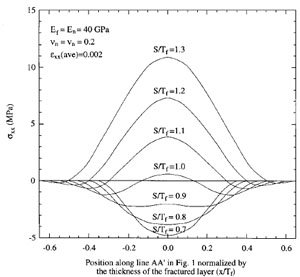

There are two very important concepts related to the growth of joint arrays or sets. One of these is the notion of fracture saturation (see Figure 1) which corresponds to a critical level of joint production beyond which the number of joints does not change appreciably and the additional extension is accommodated by increasing joint aperture. In layered rocks, in which layering may be due to either depositional or mechanical processes, joint spacing to layer thickness ratio appears to level off around 1 for well developed joint systems. In such systems the spacing or density of joints is controlled by the height of the joints. The basis of this rule is known as the stress shadow which is a zone of stress relief around a fracture, the width of which scales with the height of the fracture (Lachenbruch, 1962; Nur, 1982) as presented somewhere else in this Knowledgebase. Perhaps the best example of this phenomenon can be seen in the so-called joint elimination in an array of joints initiating from a surface or boundary and growing towards the interior of the medium in such a way that the relief zone width or joint spacing increases by systematic termination of certain other joints (Figures 2a and b). Figure 2c is a plot showing the normalized opening mode fracture propagation energy at one of the tips (the upper tip in this case, however, the problem is symmetric) of initial fractures assumed to be the same length (2a) and spacing (2b) for a certain incremental extension (2c) of the central fracture (number zero). As the ratio of c/a increases from 0.2 to 2.0, the relative propagation energy associated with the joints closer to the central fracture decreases systematically (DeGraff, 1987) implying that the closer fractures are less likely to propagate than those farther away marked by higher numbers. There are two processes in play in the evolution of joint spacing: One is related to in-plane joint propagation due to stress concentration at existing joints tips and the other has to do with the initiation of new joints in between existing subparallel joints, which is often referred to as joint infilling. It turns out that there is a limit for joint infilling (Bai and Pollard, 1999) corresponding to the state of joint saturation. Bai (1999) and Bai and Pollard (2000) showed based on their numerical modeling results that when joint spacing to layer thickness ratio changes from greater than a critical value to less than that, the normal stresses acting perpendicular to the joints within the slab between the neighboring joints change from tensile to compressive (Figure 3 and Figure 4). This switch in the stress state precludes further joint infilling. | |||||||

| Reference: |

|||||||

| Bai, T., 1999 Bai, T., Pollard, D.D., 2000 DeGraff, J.M., 1987 DeGraff, J.M., Aydin, A., 1993 Lachenbruch, A.H., 1962 Nur, A., 1982 Wu, H., 1993 Wu, H., Pollard, D.D., 1995 |

|||||||

|

Readme | About Us | Acknowledgement | How to Cite | Terms of Use | Ⓒ Rock Fracture Knowledgebase |

|||||||