| |||||||

|

|

|||||||

|

|

|||||||

| Termination of Joints | |||||||

|

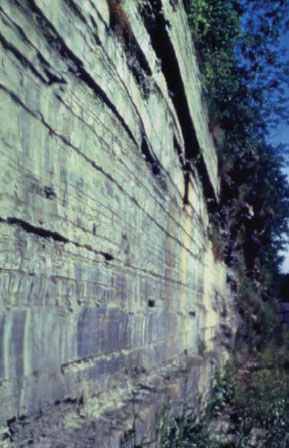

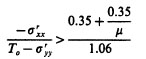

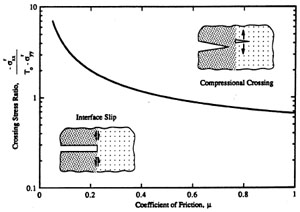

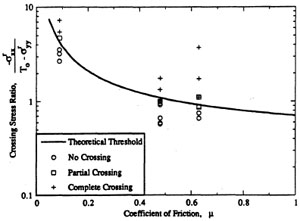

Joints arrest or terminate because of decreasing driving energy or increasing fracture toughness across the interface between jointed and unfractured layers. Some other factors that cause joints to terminate include increasing confining pressure, decreasing pore fluid pressure, fracture tip blunting, fracture tip process zone, low frictional strength of interfaces, increasing temperature, ductility, or viscosity. Even in relatively homogeneous layers, interactions among nearby joints would decrease the joint tip stresses thereby promoting terminations. To see examples for joint terminations due to interaction between nearby joints, please see 'Interaction of Joints.' Joints in layered rocks commonly terminate when intersecting other joints or layer interfaces (Figure 1). However, other conditions such as joint or interface perpendicular stresses play a critical role in these cases (Figure 2). Renshaw and Pollard (1995) provide a simple criterion for predicting whether a joint will propagate across a frictional interface oriented perpendicular to the approaching joint by analyzing the linear elastic fracture mechanics solution of the stresses near the joint tip and confirming with experimental results. The analysis assumes a joint will cross a frictional interface if the magnitude of the compression acting perpendicular to the interface is sufficient to prevent slip along the interface at the moment when the stress ahead of the fracture tip is sufficient to initiate a fracture on the opposite side of the interface. The theoretical crossing criterion, as formulated in Equation 1, is a function of stress ratio, tensile strength of the material on the opposite side, and the friction on the interface. The criterion is plotted in Figure 3 as a function of the friction coefficient. Renshaw and Pollard also verified this crossing stress ratio criterion via experiments. Three molded planks of brittle material were subjected to compression normal to their longest dimension. A hole in the center plank was used to initiate a fracture which propagated towards the interfaces between the planks. The fracture was driven by a wedge device inserted into the hole in the center plank. The behavior of the fracture as a function of the amount of compression applied across the interface was then recorded. By repeating this experiment using different brittle materials or lubricating the interface, the critical amount of compression required for compressional crossing, as a function of both material tensile strength and interface friction coefficient, was determined. Their experimental results are summarized in Figure 4, indicating the theoretical threshold being consistent with the laboratory data. | |||||||

| Reference: |

|||||||

| Helgeson, D., Aydin, A., 1991 Renshaw, C., Pollard, D.D., 1995 |

|||||||

|

Readme | About Us | Acknowledgement | How to Cite | Terms of Use | Ⓒ Rock Fracture Knowledgebase |

|||||||